Safe Asbestos Abatement for Renovation Projects

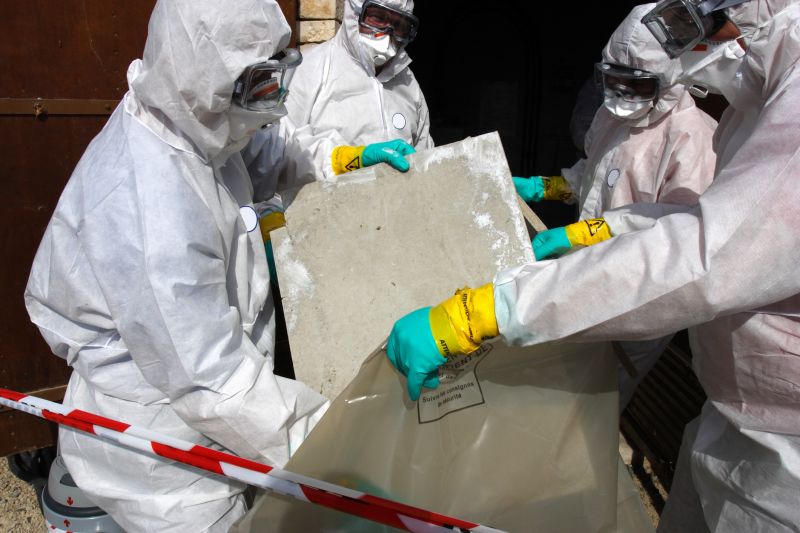

Multiple layers of protective gear and specialized equipment are used to safely remove asbestos materials, minimizing exposure risks.

Containment barriers and negative air pressure systems are employed to prevent asbestos fibers from spreading to surrounding areas.

Post-removal inspections ensure all asbestos materials have been properly removed and the area is safe for occupancy.

Asbestos abatement involves the safe removal and disposal of asbestos-containing materials from buildings. This process is critical in preventing health issues related to asbestos exposure, which can include respiratory diseases and cancers. Proper abatement is essential in renovations, demolitions, or when asbestos materials are damaged or deteriorating. The complexity and health risks associated with asbestos make professional intervention highly recommended.

Statistics indicate that thousands of buildings still contain asbestos materials, often hidden within insulation, flooring, or ceiling tiles. The removal process must adhere to strict safety standards to protect workers and occupants. On average, a professional asbestos abatement can take anywhere from a few days to several weeks, depending on the size and complexity of the project. Accurate planning and execution are vital to ensure complete removal and safety compliance.

Initial assessment involves identifying asbestos-containing materials through detailed inspections and laboratory testing.

The work area is sealed off with barriers, and specialized ventilation systems are installed to prevent fiber spread.

Trained professionals carefully remove asbestos materials using appropriate protective gear and dispose of them following regulatory guidelines.

Post-removal testing ensures all asbestos has been eliminated, and the area is safe for occupancy.

Engaging experienced professionals for asbestos abatement ensures the process is conducted safely, efficiently, and in compliance with all regulations. Proper removal reduces health risks and prevents costly future remediation. Professional teams utilize specialized equipment and follow strict protocols to contain asbestos fibers and prevent contamination.

Advanced tools and containment systems are used to safely extract asbestos materials.

Abatement professionals wear full protective gear to prevent exposure during removal.

Inspection and testing confirm the area is free of asbestos fibers after removal.

The importance of professional asbestos abatement cannot be overstated. Proper procedures protect health, ensure regulatory compliance, and prevent future liabilities. The process requires meticulous planning, specialized training, and adherence to safety standards. Failure to properly remove asbestos can lead to legal issues, health hazards, and costly remediation efforts.

Professionals have the training and experience to handle complex asbestos removal projects safely.

Adherence to all safety and disposal regulations ensures legal compliance and reduces liability.

Proper containment and removal techniques minimize exposure risks for occupants and workers.

Experienced teams complete projects efficiently, reducing downtime and unexpected expenses.

Proper asbestos abatement is a specialized task that demands professional expertise. Engaging trained specialists ensures the work is done thoroughly, safely, and in compliance with all applicable regulations. This approach not only protects health but also mitigates legal and financial risks associated with improper removal.

Photos of safe, professional asbestos removal in various building types.

Showcases the protective gear and containment systems employed during abatement.

Visual evidence of clearance testing and certification after abatement.

Interested in a quote for asbestos abatement services? Filling out the contact form provides an opportunity to discuss project specifics, timeline, and requirements. Professional guidance ensures a safe and compliant removal process tailored to individual building needs.